CNC Machining Services

CNC machining uses computer-guided, automated tools to manufacture various components made from different materials. This process is essential to many industries, and at Pro-Cise, our experts deliver superior results for every project. Learn more about our capabilities and why Pro-Cise is the right choice for precision machining services.

Request A Quote

Overcoming Machining Hurdles

As an original equipment manufacturer (OEM), working with a third-party machining expert is an easy way to handle your component production. While these machining companies help you offload responsibilities, they might not offer everything you need. Some businesses lack the experience and tooling necessary for creating complex components.

This lack of expertise and equipment often translates to slower production rates and reduced safety practices. At Pro-Cise, we address these challenges. Our qualified CNC machinists work safely and efficiently on every project, and we apply a creative approach when complex components demand it.

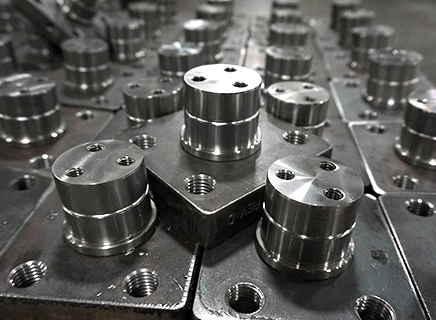

Precision CNC Machining for OEMs

Pro-Cise delivers precision CNC machining services for medium- to large-scale OEM applications. Our professionals bring decades of experience and a strong background in reading geometric dimensioning and tolerancing (GD&T) to every task. This expertise translates your complex drawings into reality using state-of-the-art machinery and innovative techniques. Our cutting-edge capabilities reduce material waste, minimize machining time and maintain in-tolerance accuracy for every production run.

CNC Technology Advancements

Machining technology continues to evolve, and Pro-Cise stays at the forefront with state-of-the-art equipment that enhances efficiency and precision. Our facility features five-axis mills with up to 120 inches of travel and four-axis lathes with radial and axial live tooling, ensuring we can accommodate complex geometries and features in a single setup.

We integrate the latest advancements in automation, tooling and real-time monitoring to optimize production speed and consistency. Automated tool changers and adaptive machining techniques allow for tighter tolerances, reduced cycle times and improved repeatability. These innovations ensure that every part we produce meets the exacting standards required in metal machining services for OEM applications.

Material Sourcing

Pro-Cise has established a diverse material vendor network, allowing us to efficiently source specialized or high-demand materials required for OEM part manufacturing. We source a wide range of materials, including:

- Carbon and stainless steel: These metals are ideal for structural components, wear-resistant parts and high-strength applications.

- Aluminum and copper alloys: These alloys suit lightweight designs requiring excellent conductivity and corrosion resistance.

- Exotic alloys: These materials, such as Inconel, Monel and Duplex Stainless 2205, are essential in extreme environments where heat, pressure and chemical exposure pose significant challenges.

Material traceability is a critical part of our contract machining services. We provide full documentation of materials, from procurement through final machining. We track every material batch with lot numbers, supplier details and documentation, ensuring complete transparency and accountability.

Quality Assurance in CNC Machining

Every component we machine undergoes rigorous inspection using cutting-edge equipment. Our quality control practices include:

- A dedicated quality lab: Our specialized quality lab is equipped with advanced inspection technology, including coordinate measuring machines (CMMs), to validate every component before it moves to the next production stage.

- ISO 9001 quality management system: All our processes adhere to ISO 9001-certified standards.

- First article inspection (FAI) with documentation: We validate the design and manufacturing processes with all required paperwork and inspection reports prior to releasing to full-scale production.

- Non-destructive testing (NDT): We utilize ultrasonic, radiographic and magnet particle testing for structural integrity verification.

By integrating these quality control measures, Pro-Cise guarantees high-precision machining that meets OEM performance and durability requirements.

Complex Machining Capabilities for OEMs

At Pro-Cise, we are experts in large component machining, handling parts up to 22,000 pounds on horizontal machining centers and 20,000 pounds on vertical machining equipment. We also excel in machining components with complex shapes and unique design requirements.

Our experienced machinists bring creative problem-solving to every project, delivering precision CNC machining services for parts that push the boundaries of conventional manufacturing. This specialized approach allows us to provide cost-efficient, production-ready solutions for OEMs requiring exceptional accuracy and consistency.

Why Choose Pro-Cise Machining Services?

Developing machining skills at your facility requires company resources you may not have access to. Outsourcing your machining needs to a third party can offer several advantages. Pro-Cise stands out among metal machining providers for our ability to tackle complex challenges that other providers avoid. Our metal machining services are:

- Accurate: With our extensive quality control and inspection services, you can trust our machinists to deliver a precise component every time. We ensure your final product matches your drawing with appropriate tolerances and withstands performance requirements. Extensive experience also leads to reduced human errors.

- Consistent: The CNC machinists at Pro-Cise have years of experience with complex drawings and parts. They know the techniques that lead to excellent results and use them for every project, regardless of scope. Established inspection processes ensure consistency across the board.

- Efficient: Timelines are just as valuable to a project as a part’s quality. Our equipment and skills allow us to deliver components within your time frame so your operation can keep up with demand.

- Scalable: We handle full-scale OEM production with short lead times.

- Comprehensive: We manage the entire production process, from material sourcing to final inspection and secure shipping.

Industry Applications for Complex Machining Services

Machine tool automation delivers superior results, making it valuable to many industries. Use our custom CNC machining for:

Work With Pro-Cise for OEM Contract Machining Services

Pro-Cise is the trusted partner for OEMs seeking CNC machining services that deliver precision, reliability and scalability. With advanced machining capabilities, industry-leading quality control processes and dedication to ongoing improvement, we provide solutions tailored to demanding manufacturing needs. Contact us today to request a quote or to discuss your project with our experts.