Metal Cutting Capabilities - A Cut Above

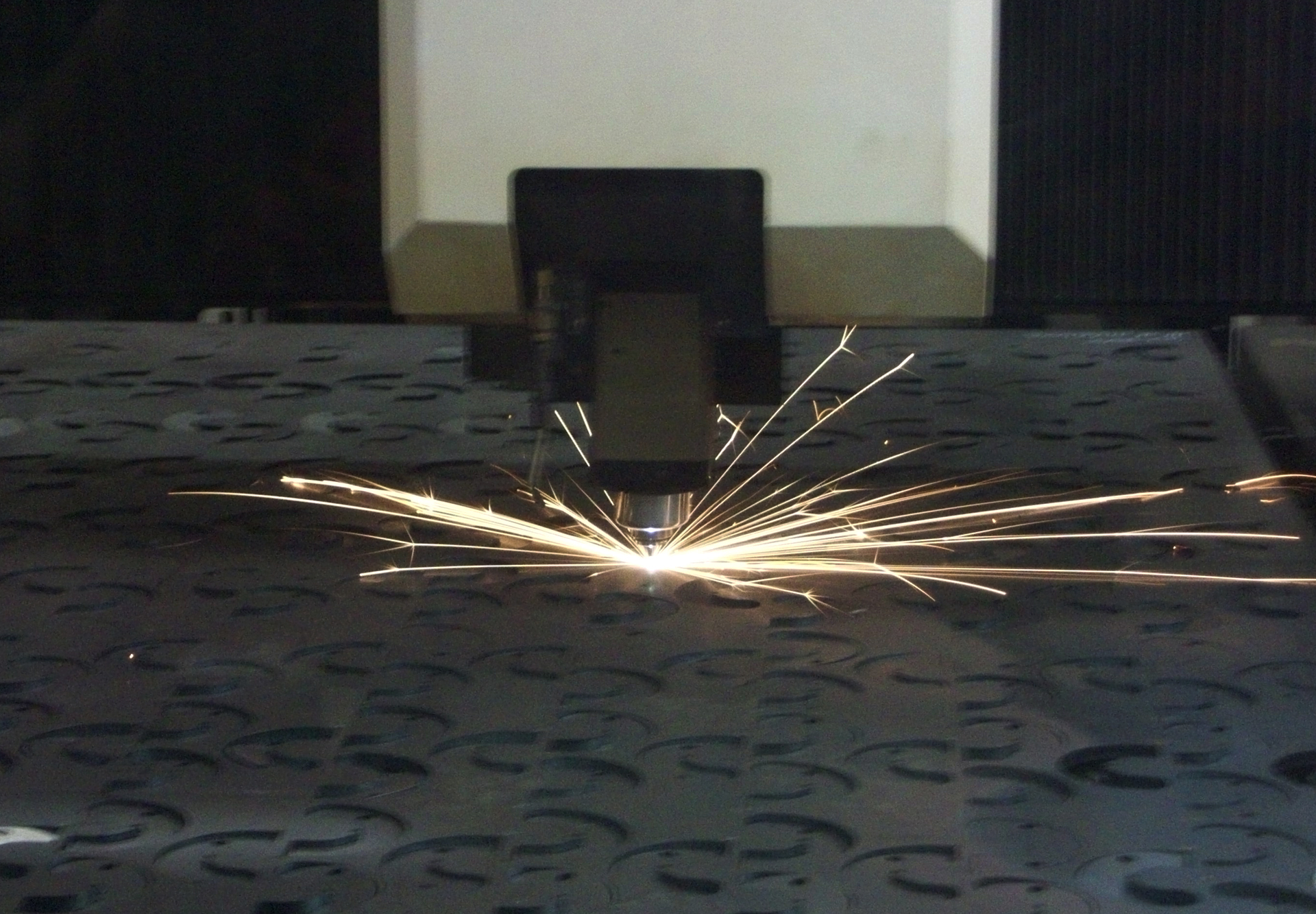

Pro-Cise sets the standard for precision and efficiency in metal laser cutting services, delivering tailored solutions for medium and large-scale OEMs.

At Pro-Cise, we offer many advanced services for your manufacturing needs. Our custom laser cutting services are at the forefront of metal cutting technology. With our experienced professionals and advanced equipment, you can trust us to support your project with precision.

Request a Quote

Overcoming Traditional Cutting Hurdles

Before laser cutting, professionals relied on traditional methods like sawing and milling. While these techniques help manufacturers achieve the needed cuts, they’re not always accurate. As manufacturing demands rise, these methods fall behind many businesses’ tight schedules, causing companies to lag behind competitors in their industries.

While fabricators may attempt to keep up with production demands, traditional cutting techniques come with serious safety concerns. Working quickly can risk technicians’ safety. Laser cutting addresses these hurdles, giving manufacturers a safe, fast and consistent cutting method for any project’s needs.

Pro-Cise’s Expertise in Large-Scale Laser Cutting

Pro-Cise supports medium to large OEMs by delivering large-scale laser cutting services with advanced technology and highly trained technicians. Our methods focus on accuracy and speed, helping companies meet production targets on tight timelines.

Decades of Metal Cutting Experience

Pro-Cise leverages decades of experience to provide exceptional metal laser cutting services to OEMs in diverse industries. Our cutting-edge equipment allows us to handle complex part profiles and large-scale projects with ease. This capability makes us a trusted partner for OEMs requiring high-volume, precise and repeatable components. We specialize in creating solutions that seamlessly integrate with assembly-level manufacturing processes.

Design Considerations

Strategic part layout and precise measurements are key in metal laser cutting for OEMs. We collaborate closely with companies to address key design factors such as material thickness, cut complexity and tolerances. Our design team utilizes sophisticated CAD software to optimize your designs for laser cutting, ensuring dimensional accuracy, consistent repeatability for all production runs and minimal material waste.

Material Compatibility

Pro-Cise offers extensive expertise in working with a wide range of materials, making us one of the leading metal cutting companies. Our material capabilities include:

- Carbon steel

- Stainless steel

- Aluminum

- Bronze

- Brass

- Copper

Do you need metal cutting for other materials not listed above? Reach out to our team to discuss your unique material requirements.

Beyond cutting, our expertise extends to sheet metal fabrication and metal forming, allowing us to deliver fully finished parts that satisfy your manufacturing needs. Whether you require lightweight aluminum components or heavy-duty stainless steel parts, our facility is equipped to deliver superior results.

Company Certifications

Pro-Cise is committed to maintaining the highest standards of quality and excellence, as demonstrated by our extensive range of industry certifications. We hold and continuously maintain the ISO 9001 certification, which reflects our robust quality management system and dedication to delivering top-tier metal cutting services. This certification guarantees that our commercial laser cutting service consistently meets international quality and efficiency standards.

Our prowess is further validated by certifications from the American Welding Society (AWS), showcasing our advanced welding techniques and proficiency in metal fabrication. We are also proud to hold the American Bureau of Shipping (ABS) Type Approval certification and the DNV.GL Part Certification, both of which affirm our capability to produce safe and high-performance metal components that adhere to stringent industry requirements.

These certifications highlight Pro-Cise’s unwavering commitment to quality and reliability in our metal laser cutting services, providing our clients with confidence in the precision and consistency of our work. By maintaining our high standards, Pro-Cise meets and often exceeds the expectations of our customers, solidifying our reputation as a trusted leader among metal cutting companies.

Precision Laser Cutting Services With Pro-Cise

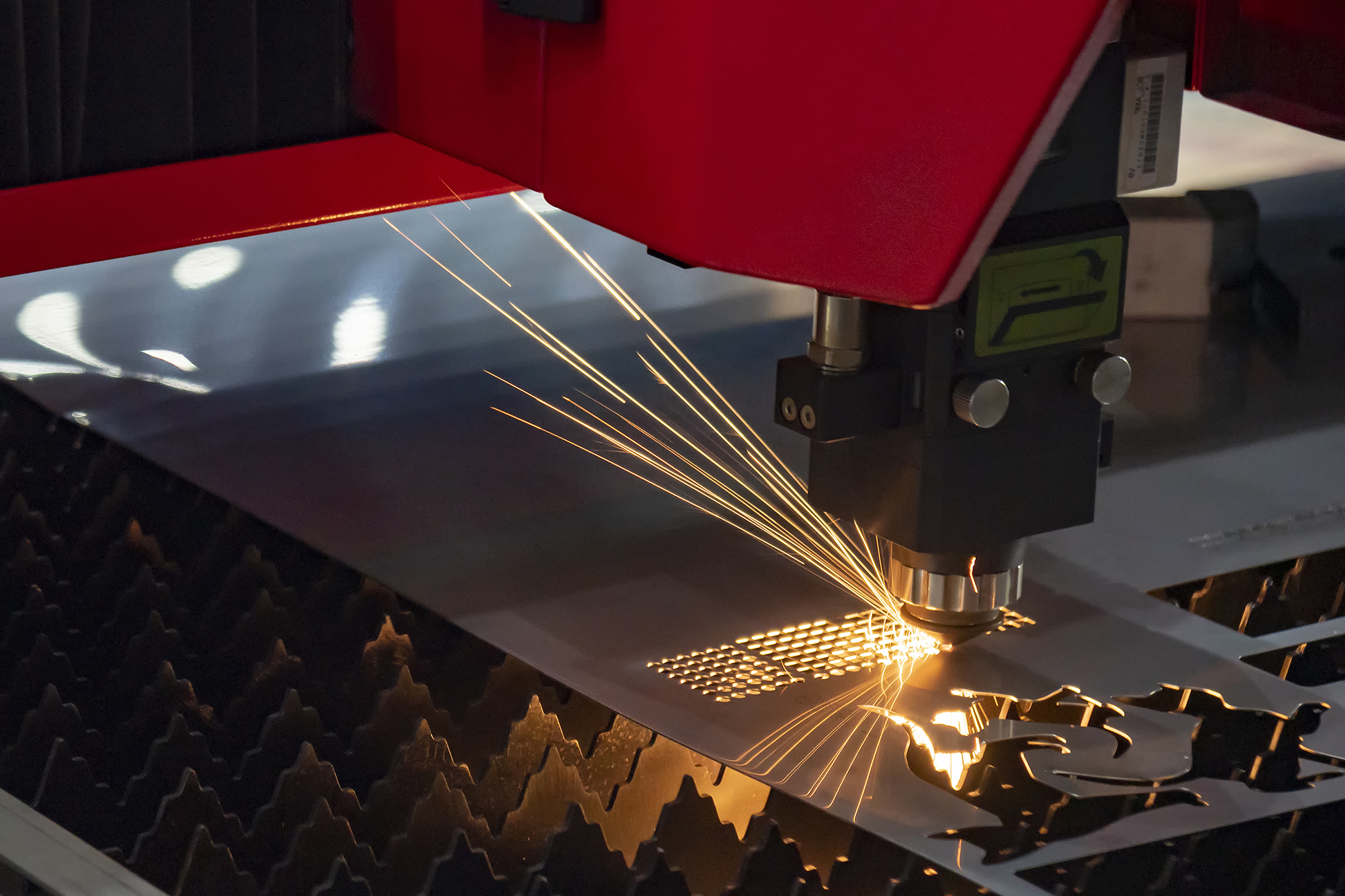

At Pro-Cise, our experienced staff members utilize laser cutting technology for the best results. We have two in-house laser cutting machines offering power and precision. When we receive your specs, we can use one or both models to achieve cutting accuracy.

Our equipment includes:

- Mazak 3015 Optiplex 4,000W CO2 Laser (60″ x 120″)

- Mazak 3015 Optiplex 6,000W Fiber Optic with 2 pallet changer (60″ x 120″)

In addition to our laser cutting technology, we provide laser cutting services with material traceability at your request.

Pro-Cise Laser Cutting Service Benefits

Precision laser cutting services offer many advantages to manufacturers. These benefits include:

- Material utilization: The nature of laser cutting allows our manufacturers to cut arrays or patterns of parts and make the most of all materials.

- Repeatability and accuracy: While our cutting machines offer more precision than other techniques, we can also repeat orders with the same level of accuracy every time.

- Speed: Laser cutting is an efficient process that supports short lead times, so you receive your order sooner. As demand for your products grows, laser cutting allows us to keep up with your component requirements.

- Non-contact cutting: A laser cutting beam cuts with heat. This non-contact approach means minimal damage to the final product and fewer costs related to repairs and maintenance.

Industry Applications for Custom Laser Cutting Services

With laser cutting’s versatility and accuracy, many industries rely on the process to manufacture components and equipment. Laser-cut parts often contribute to larger assemblies and mechanical components across industries. These sectors include:

At Pro-Cise, our advanced equipment and experienced team ensure we deliver the tight tolerances, quantities and efficiency rates these industries need for their respective components.

Why Trust Pro-Cise for Metal Laser Cutting Services?

Pro-Cise is a trusted partner for OEMs needing reliable metal cutting services. Here’s what sets us apart:

- Advanced technology: Our CO2 and fiber-optic laser cutting machines provide precise, repeatable cuts for projects of any complexity, ensuring consistent, high-quality results.

- Proven expertise: Decades of experience and a skilled team allow us to handle intricate designs and collaborate closely with OEMs to meet exact specifications.

- Versatile materials: From carbon steel and stainless steel to specialty metals like brass and aluminum, we work with a variety of materials to suit diverse project needs.

- Collaborative partnership: We value clear communication and long-term relationships, making us a trusted partner who can support your success.

- Comprehensive project support: Our staff coordinates from initial design to final inspection, guiding OEMs through each step for smooth communication and consistent part quality.

Choose Pro-Cise as Your Laser Cutting Company

At Pro-Cise, we're more than a laser cutting company. We support manufacturers with our extensive portfolio of services, from welding and machining to finishing and assembly. When you need a reliable project partner, Pro-Cise offers the expertise, equipment and quality control you need for specialized components. Contact us today to learn more or get a quote for our custom laser cutting services.